Specialists in Industrial Automation Machinery & Solutions

About us

Who we are

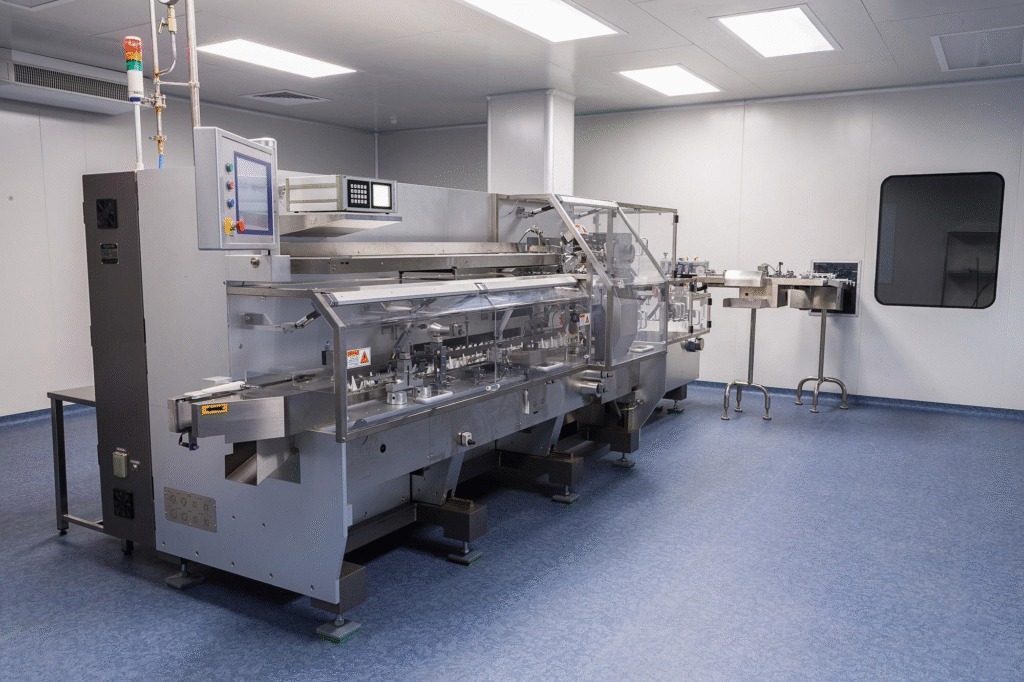

Welcome to the world of innovation and precision! In the ever-evolving landscape of industry, our manufacturing company stands tall as a beacon of excellence, pushing the boundaries of what’s possible and redefining the future of production.

At INTECH AUTOMATION MACHINERY we pride ourselves on being a dynamic and forward-thinking organization dedicated to delivering high-quality products and solutions to our global clientele. With years of experience and expertise in the manufacturing domain, we have garnered a reputation for being a reliable partner, meeting the diverse needs of our customers across various sectors.

Our commitment to innovation is at the heart of everything we do. From cutting-edge technologies to state-of-the-art machinery, we have embraced the latest advancements to streamline processes and maximize efficiency. We believe that by continuously adapting to emerging trends and embracing change, we can stay ahead in a competitive marketplace and offer the best value to our clients.

Our Product

Innovation Meets Simplicity

Online Cap Tightening Machine

Precision liquid filling systems for various container sizes and product viscosities.

Automatic Screw Capping Machines

Fully automated screw capping system with multiple head options for different bottle sizes.

Automatic ROPP Capping Machines

Specialized equipment for roll-on pilfer-proof caps with precision threading.

Detergent Liquid Soap Bottle Capping Machine

Heavy-duty capping solution for high-viscosity products like detergents.

Dispenser Pump Capping Machine

Specialized equipment for securing dispenser pumps to bottles.

Liquid Filling Machines

Precision liquid filling systems for various container sizes and product viscosities.

Solid Filling Machine

Automated systems for accurate filling of powders, granules and other solid materials.

Automatic Collating and Over Wrapping Machine

Automated system for collating products and applying protective overwrap.

Auto Cartoning Machine

Automatic carton forming, filling and sealing system for various product sizes.

Automatic Soap Bar Cutter

High-speed cutting system for soap bars with precise dimension control.

Automatic Soap Collating and Overwrapping Machine

Complete solution for collating and wrapping soap bars in protective packaging.

Glycerine Soap Bar Cooler

Temperature-controlled cooling system for glycerine soap production.

Glycerine Soap Bar Cutting Machine

Precision cutting equipment for glycerine soap bars with minimal waste.

Soap Stamping Manual Press

Manual press for stamping logos and designs onto soap bars.

Hand Made Soap Cutting Machine

Specialized cutter for artisanal and handmade soap production.

Glycerine Soap Flash Cutting Machine

High-speed cutting system for glycerine soap with flash cooling.

Tablet Counting, Filling and Capping Machine

Complete system for counting, filling and capping pharmaceutical tablets.

Effervescent Tablet Counting, Filling and Capping Machine

Specialized equipment for handling effervescent tablets with moisture

Cartoning Machine

High-speed cartoning system for pharmaceutical product packaging.

Universal Mixers

Versatile mixing equipment for various industrial applications.

Multi Purpose Mixers

Flexible mixing systems capable of handling multiple product types.

Contra Mixers

High-efficiency contra-rotating mixers for thorough blending.

High Speed Mixer

Rapid mixing equipment for time-sensitive production processes.

Slow Speed Mixers

Gentle mixing systems for delicate products and materials.

Storage Tanks

Industrial-grade storage tanks in various sizes and materials.

Silo Tanks

Large-capacity silo tanks for bulk material storage.

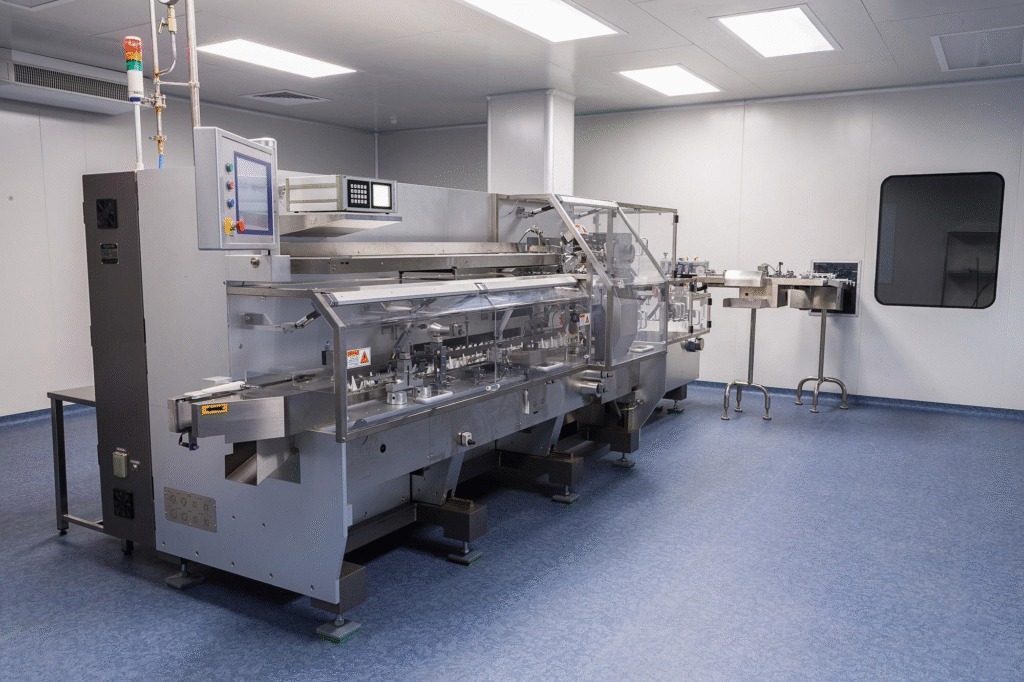

Design & Development of Automation Machinery

Professional Team

We have a team of 5 project engineers, 3 execution engineers & over 20 experienced technicians & fitters.

Solution Support

We have a team of 5 project engineers, 3 execution engineers & over 20 experienced technicians & fitters.

Infrastructure

We have a team of 5 project engineers, 3 execution engineers & over 20 experienced technicians & fitters.

Identify Core Features

We have a team of 5 project engineers, 3 execution engineers & over 20 experienced technicians & fitters.

Why Choose Us

Creative and Unique Solutions

Certainly! As an innovative and forward-thinking manufacturing company, we offer several distinct advantages that set us apart from the competition. Here are some of the key benefits of choosing our company:

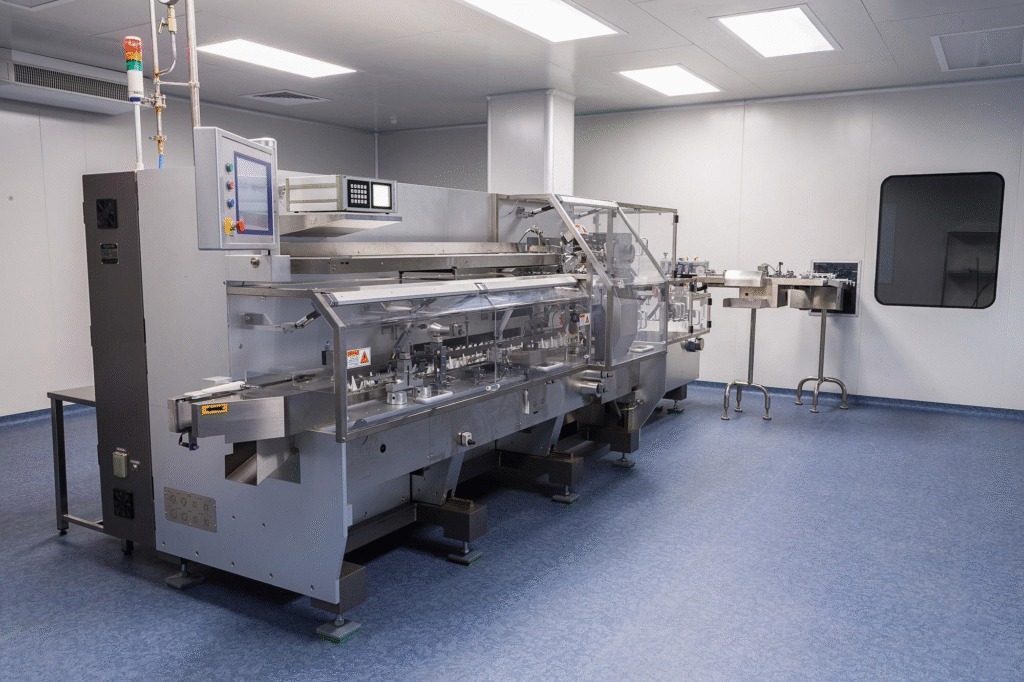

Cutting-Edge Technology

We invest heavily in the latest cutting-edge technologies and state-of-the-art machinery. This allows us to optimize our manufacturing processes, enhance product quality, and increase production efficiency. Our commitment to staying at the forefront of technological advancements ensures that our clients benefit from the most advanced solutions available.

Skilled Workforce

Our company boasts a highly skilled and experienced workforce. From engineers to technicians and designers, our team members are experts in their respective fields. Their dedication to craftsmanship and attention to detail guarantee that every product we deliver is of the highest standard.

Customization and Flexibility

Quality Assurance

Our Approach

Approach Towards Designing of machines

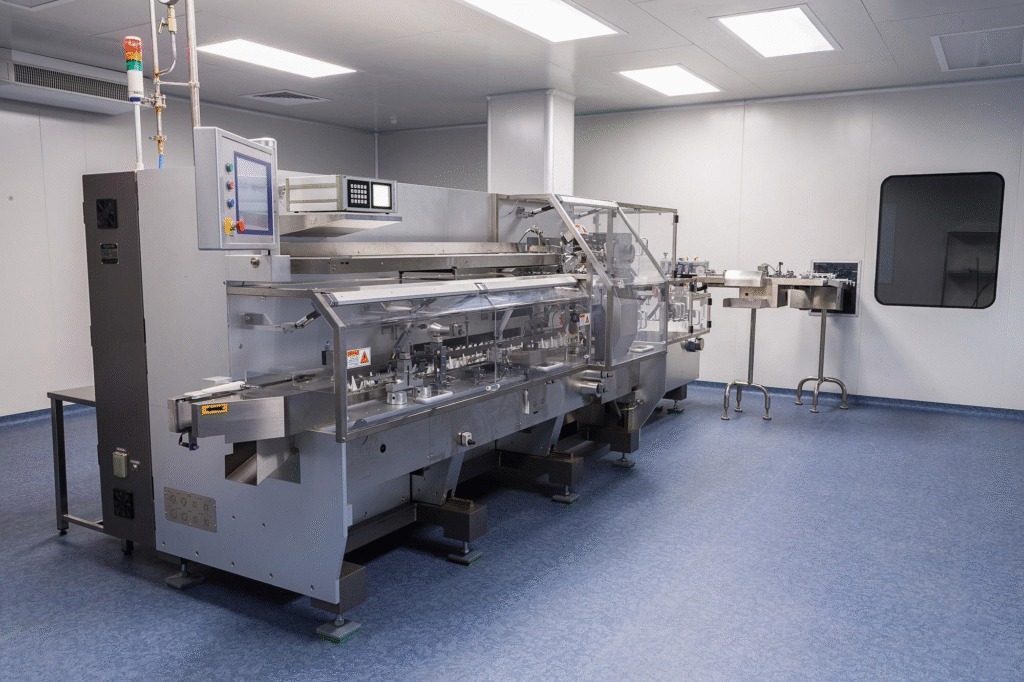

Designing machines is a complex and multidisciplinary process that involves the creation of functional, efficient, and safe devices to perform specific tasks or processes. Whether it’s a simple mechanical tool or a sophisticated automated system, the design process follows a systematic approach to ensure the successful realization of the intended machine.

Understanding the Purpose

Research and Conceptualization

Once the purpose is clear, thorough research is conducted to explore existing solutions and technologies. This research helps designers identify potential design ideas, gather inspiration, and understand the state-of-the-art in relevant fields. During this phase, concept development takes place, which involves brainstorming and sketching different design concepts.

Feasibility Analysis

Detailed Design

Materials and Components Selection

Prototyping

Before moving to full-scale production, a prototype of the machine is built. Prototyping allows designers to test and evaluate the functionality and performance of the design in real-world conditions. It also helps identify potential flaws and areas for improvement.

Testing and Iteration

Safety and Compliance

Manufacturing and Production

Quality Assurance

Installation and Maintenance Considerations

Documentation and Manuals

Transform Your Operations Today! Explore Our Automation Solutions

View our latest news

Download Our Knowledgeable Browser

Your Filling Machine Search Starts Here

More Browser

The Hidden Sources of Love, and Achievement

The Hidden Sources of Love, and Achievement

The Hidden Sources of Love, and Achievement

Your Filling Machine Search Starts Here

More Browser

The Hidden Sources of Love, and Achievement

The Hidden Sources of Love, and Achievement

The Hidden Sources of Love, and Achievement

Your Filling Machine Search Starts Here

More Browser

The Hidden Sources of Love, and Achievement

The Hidden Sources of Love, and Achievement

The Hidden Sources of Love, and Achievement

Your Filling Machine Search Starts Here

More Browser

The Hidden Sources of Love, and Achievement

The Hidden Sources of Love, and Achievement

The Hidden Sources of Love, and Achievement

Frequently Asked Questions

Frequently Asked Questions

How do industrial robots work?

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud pede justo vel fringilla aliquet nec vulputate imperdiet a venenatis ullamcorper ultricies nisi libero venenatis faucibus eget eros faucibus tincidunt commodo ligula eget dolor.