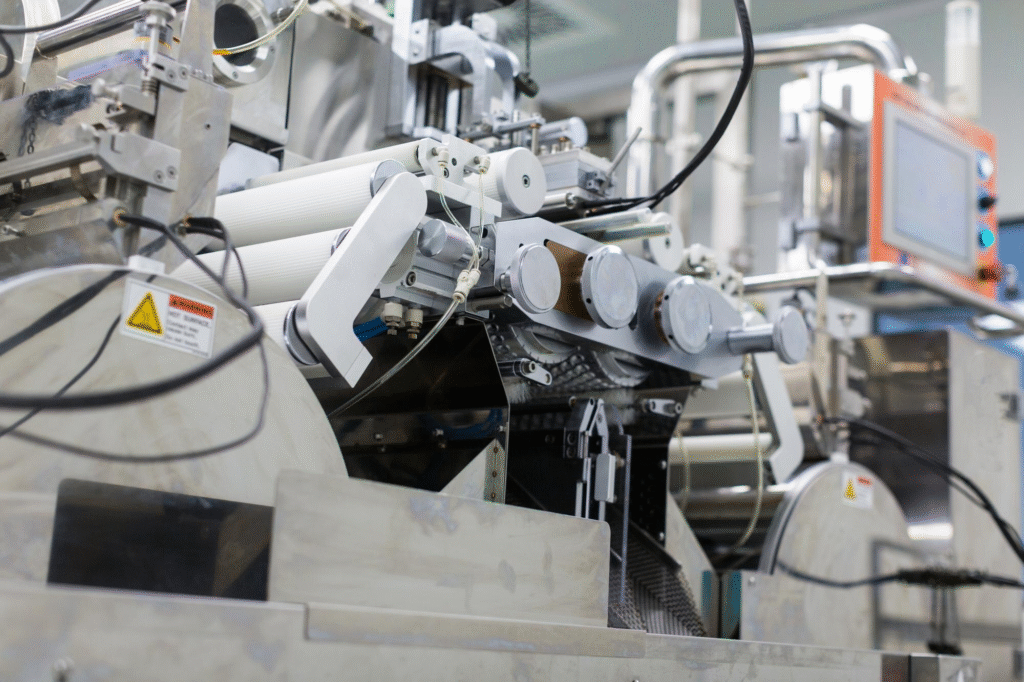

Boosting Productivity Through Automation

In today’s fast-paced industrial landscape, productivity is a key performance indicator, and automation is proving to be its strongest ally. By replacing repetitive tasks with machines, companies can significantly enhance speed, accuracy, and output. Automation minimizes human error, streamlines operations, and ensures consistent product quality. Whether it’s robotic arms on the assembly line or software bots handling reports, the right automation tools free up your workforce to focus on innovation and strategy. With automation, businesses gain agility, reduce operational costs, and meet customer demands more efficiently. It’s not just about doing things faster — it’s about doing them smarter. Key Points: Automation reduces operational delays. Enhances consistency and reduces defects. Robots and bots increase task throughput. Improves employee focus on value-added tasks. Lowers labor costs and enhances scalability. Faster delivery times improve customer satisfaction. Increases overall equipment efficiency (OEE).